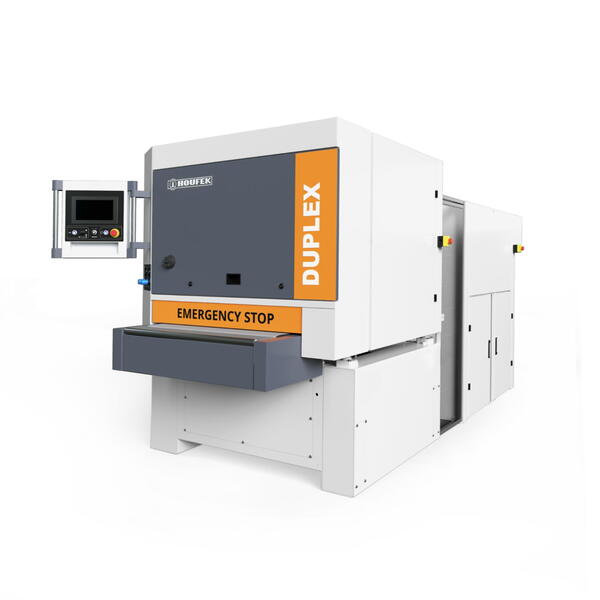

Wide belt sander Duplex 1100

Massif Wood Veneer

Duplex is highly efficient wild-belt sander designed for double sided sanding of mostly board materials. The construction of Duplex is based on Buldog series and the application of double sided sanding increases the work productivity. The permanent desk height enables to use the Duplex in technological lines. The surface sanding quality and high level of automation ranks the machine in the highest class.

Product benefits

We produce the machine since 2007

We delivered the machine to 19 of the world's countries

We produced the machine for 60 of satisfied customers

Use

Wide-belt sander Duplex is designed for:

- sanding workpieces made from wood, wood base composite materials, paper and some plastic materials and metals

Interesting product

- efficient machine for double sided sanding, produced in wide range of variants

Specifications

| Working width | 1 100 mm |

| Sanding belt width | 1 120 mm |

| Sanding belt length | 2 620 mm |

| Contact roller diameter | 160 mm |

| Maximum workpiece height | 160 mm |

| Min. workpiece height | 10 mm |

| Sanding unit motor power | 4 × 11 kW |

| Sanding belt speed | 18,5 m/min |

| Operating pressure | 5,5 bar |

| Exhaust air speed | 20 m/s |

| Motor power | 11 kW |

| Voltage / frequency | 3/N/PE 400V/50Hz V / Hz |

| Weight | 4 850 kg |

3D Model

Standard equipment

- two sanding units : 1. Type R , 2. Type C + adjustable base – top part

- two sanding units : 1. Type R , 2. Type C + adjustable base – lower part

- 1. operating roller rubber coated D=160 mm, 90Sh

- 2. operating roller rubber coated D=160 mm, 45Sh

- NC-machine control colour Touschscreen 10,4"

- sanding belt width 1900 mm

- min. Workpiece length 300 mm (RR-RR), 500 mm (RC-RC)

- automatic switching - star / triangle

- ammeter for measuring the sanding unit

- motor current Oscillation control sanding belt by means of optic electric sensor with infrared beam

- fixed desk - moving sanding units

- mechanical correction of operating roller height depending on sanding belt grain size

- automatic setting of operating rollers into the pre-programmed positions

- two feeding speeds of workpiece 4,5/ 9 m/min

- rubber coated thrust rollers - 2 pcs for each sanding unit

- pneumatic disk brake of main motor

- noise pollution inspection

- standard packaging in nylon

- the machine is made according to CE standards

Optional accessories

- motor 20 HP (15 kW)

- motor 25 HP (18,5 kW)

- motor 30 HP (22 kW)

- two speeds of sanding belt 9/18 m/sec (max. 11 kw)

- two speed motor for lifting the sanding unit

- steel roller replacing the rubber coated roller D=160 mm, D=200 mm

- rubber coated roller D=160 mm 30, 45, 60, 90 Sh

- rubber coated roller D=200 mm 30, 45, 60, 90 Sh

- pneumatic base with bounce and thrust

- automatic centering of feeding belt

- thrust bars for sanding short pieces

- frequency converter of feeding belt speed 3 - 12m/min

- frequency converter of the main motor- belt speed 3 - 24 m/s

- pneumatic time blow for cleaning the sanding paper

- pneumatic time blow with nozzle oscillation for cleaning 1 sanding belt

- parts cleaning module with orbital blow

- limiting the maximum workpiece reduction

- module for cleaning parts with rotating textile or nylon brush 140 mm diameter, 1,5 kw (2 HP)

- additional inlet - outlet

- vacuum desk

- air pump

Ask about this product

45 countries

We export to 45 countries all over the worlds. Our machines run also in overseas states.

Quality

Houfek machine have unique rigid design. We care about maximum quality of all parts and components.

Service

We offer service and replacement of parts besides sales.

Cooperation

We cooperate with schools. We organize excursion and cooperate on school projects.

working roller diameter is 160 mm, optional 200 mm

working roller diameter is 160 mm, optional 200 mm

motor power 11 kW - possibility to increase to 18,5 kW

motor power 11 kW - possibility to increase to 18,5 kW